Product Category

Copper Alloy

Copper alloy is an alloy formed by adding one or several other elements to pure copper as the matrix.

Category:

Keywords:

Copper Alloy

Tel:

E-mail:

DETAILS

Copper alloy is an alloy formed by adding one or several other elements to pure copper as the matrix. Pure copper is purple-red, also known as copper. The density of pure copper is 8.96, the melting point is 1083℃, and it has excellent electrical conductivity, thermal conductivity, ductility and corrosion resistance. It is mainly used to make electrical equipment such as generators, busbars, cables, switchgear, transformers, etc. Commonly used copper alloys are divided into three categories: brass, bronze and cupronickel.

There are three classification methods of copper alloys: according to the alloy system, it can be divided into unalloyed copper and alloyed copper. Unalloyed copper includes high-purity copper, tough copper, deoxidized copper, oxygen-free copper, etc. It is called red copper or pure copper, also called red copper, while other copper alloys belong to alloy copper. In my country and Russia, alloy copper is divided into brass, bronze and cupronickel, and then small alloy series are divided into large categories.

Divided by function, there are copper alloys for electrical and thermal conductivity (mainly unalloyed copper and microalloyed copper), copper alloys for structure (including almost all copper alloys), corrosion-resistant copper alloys (mainly tin brass, aluminum brass) , various non-white copper, aluminum bronze, titanium bronze, etc.) wear-resistant copper alloys (mainly complex brass, aluminum bronze, etc. containing lead, tin, aluminum, manganese, etc.), free-cutting copper alloys (copper-lead, copper- tellurium, copper-antimony and other alloys), elastic copper alloys (mainly antimony bronze, aluminum bronze, beryllium bronze, titanium bronze, etc.) damping copper alloys (high manganese copper alloys, etc.), artistic copper alloys (pure copper, simple single copper, tin bronze, aluminum bronze, cupronickel, etc.). Apparently, many copper alloys are multifunctional.

According to the material forming method, it can be divided into cast copper alloy and deformed copper alloy. In fact, many copper alloys can be used for both casting and texturing. Usually wrought copper alloys can be used for casting, while many cast copper alloys cannot be deformed such as forging, extrusion, deep drawing and drawing. Cast copper alloy and deformed copper alloy can be subdivided into red copper, brass, bronze and cupronickel for casting.

Product parameters

|

Diameter: |

3mm-800mm,or customized |

Length: |

500-12000mm,or customized |

|

Processing: |

Custom Made |

Standard: |

ASTM,AISI,JIS,GB, DIN,EN |

|

Trademark |

C10100,C10200,C10300,C10400,C10500,C10700,C10800,C10910,C10920,C10930, C11000,C11300,C11400,C11500,C11600,C12000,C12200,C12300,C12500,C14200, C14420,C14500,C14510,C14520,C14530,C17200,C19200,C21000,C23000,C26000, C27000,C27400,C28000,C33000,C33200,C37000,C44300,C44400,C44500,C60800, C63020,C65500,C68700,C70400, C70620,C71000,C71500,C71520,C71640,C72200, T1,T2,T3,TU1,TU0,TU2,TP1,TP2,TAg0.1, |

||

|

Surface: |

Grinding, polishing, brightening, oiling, hairlining, brushing, mirroring, sandblasting or processing as required |

||

|

Certification: |

ISO.SGS.BV |

Payment Method: |

FOB,CRF,CIF,EXW are all acceptable |

|

Port Of Loading: |

Any port in China |

Delivery Time: |

Working days after receiving 30% deposit |

Chemical Composition

|

Copper Cu: |

Zinc Zn: |

Lead Pb: |

Iron Fe: |

|

|

79~81 |

Margin |

≤0.03 |

≤0.10 |

|

|

Antimony Sb: |

Bismuth Bi: |

Phosphorus P: |

Impurities: |

|

|

≤0.005 |

≤0.005 |

≤0.01 |

≤0.3 |

|

Mechanical Behavior

|

Tensile Strength σb (MPa): |

Elongation δ10 (%): |

|

≥265 |

≥50 |

Application Scope

|

|

|

Power Industry: |

|

|

Electronics industry: |

Electric vacuum devices such as high-frequency and ultra-high-frequency launch tubes, transition tubes, magnetrons, etc., require high-purity oxygen-free copper and dispersion-strengthened oxygen-free copper. |

|

Energy and petrochemical industry: |

The main condenser tube sheets and condenser tubes in thermal power plants in the energy industry are made of brass, bronze or cupronickel. |

|

Transportation industry: |

In the shipbuilding industry, copper alloys include aluminum bronze, manganese bronze, aluminum brass, gun metal (tin-zinc bronze), white copper and nickel-copper alloy (Monel), etc., which are all standard materials for shipbuilding. In warships and merchant ships, copper and copper alloys are generally used as aluminum bronze propellers, bolts, condenser tubes, rivets, copper-containing coating paint, etc. In the automotive industry, copper and copper alloys are mainly used in radiators, brake system pipelines, hydraulic devices, gears, bearings, power distribution and power systems, brake pads, washers, and various joints, accessories and trims. Motors, rectifiers and control, braking, electrical and signaling systems on railway trains also rely on copper and copper alloys to work. In addition, the electrification of railways has created a large demand for copper and copper alloys. |

|

Mechanical and metallurgical industry: |

In addition to the large amount of copper used in motors, circuits, hydraulic systems, pneumatic systems and control systems, mechanical engineering also requires various transmission parts and fixing parts, such as cylinder liners, connectors, fasteners, gears, twisting parts, etc. Use copper or copper alloy to reduce wear and lubricate. The key component in the continuous casting technology of metallurgical equipment, the crystallizer, is mostly made of high-strength and high thermal conductivity copper alloys such as chromium copper and silver copper. The vacuum arc furnace and electroslag furnace water-cooled crucible in electrometallurgy are made of copper pipes. , various induction heating induction coils are wound with copper tubes or special-shaped copper tubes, with water cooling inside. |

|

Light industry: |

|

|

Emerging industries and high-tech fields: |

|

Product advantages

Business advantage

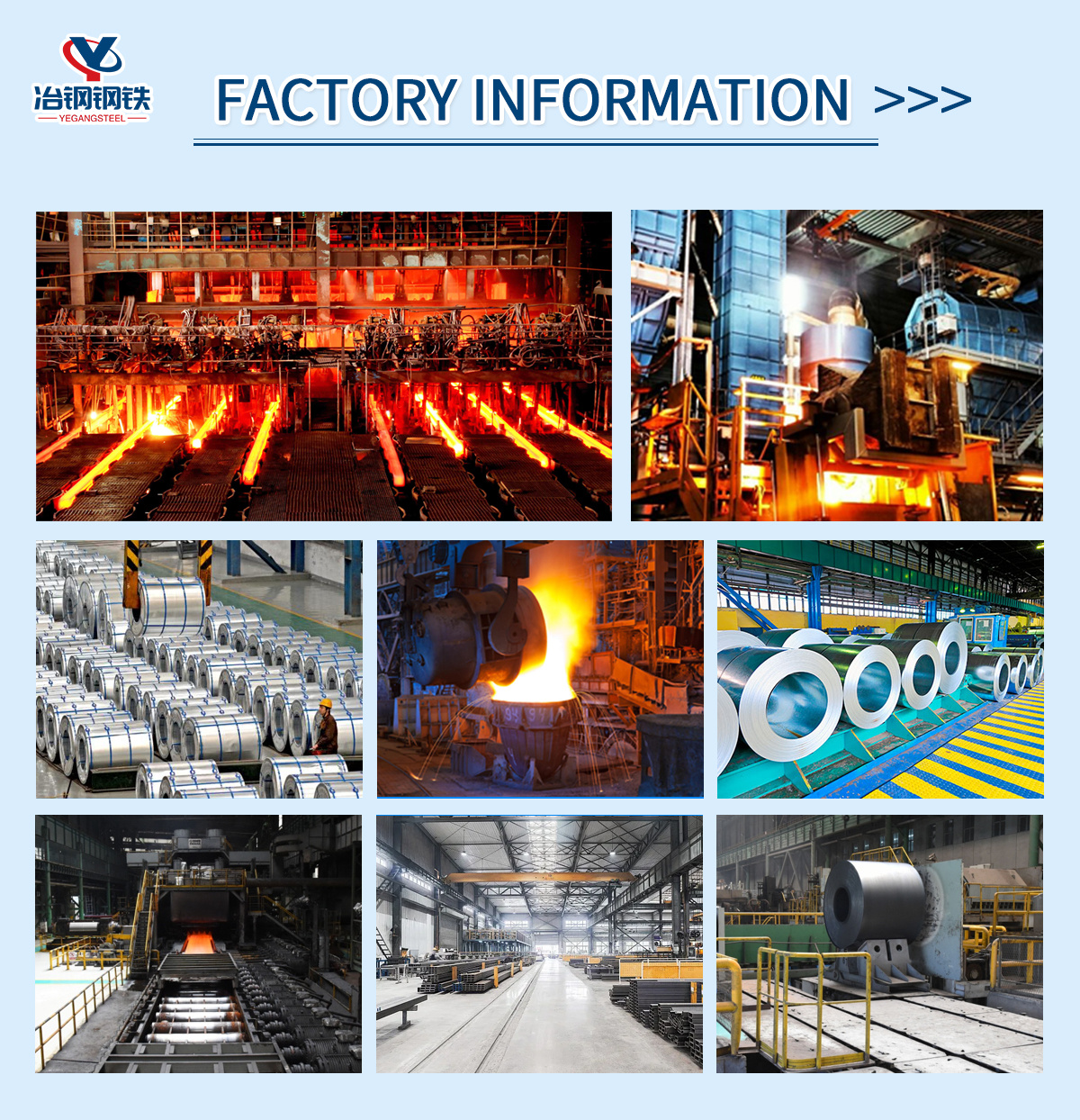

Factory information

Customer visits and certificates

Customer testimonials

Why Choose us:

1.Quality:

We are professional symbol ofChinese Metal industry; so all the supplied metal products from MAXIare quality researched & guaranteed well ones. Quality is our life. No quality, no biz.

2.Price:

Based on mature and rich acknowledge & experience forstainless steel and alloy steel, MAXIMETAL's supplied price could ensure customer has unique competitiveness in the market.As our aim is long-term biz instead of only profit by 1 or 2 order, we understand only customer win, we could win.

3.Delivery:

MAXIis one of TOP 10manufacturer of stainless steel and alloy products in China, Hold 10000tons raw materials in stock,has its own rolling factory,So enjoy high priority for delivery: Usually within 10-15from deposit date.

4.Payment:

MAXIsupply 30% TT IN ADVANCE + 70% TT WITHIN 7 DAYS OF BL DATE or IRR L/C AT SIGHT for customers. And with cooperation's growing & mature, better & better payment term will be issued, such as: L/C 30 DAYS, L/C 60 DAYS, L/C 360 DAYS, etc.

5.Service:

From MAXI, what customer could get is not only product, but also complete comprehensive marketting concept & service.

FAQ

1.What's your advantage?

A: Honest business with competitive price and professional service on export process.

2. How I believe you?

A : We consider honest as the life of our company, we can tell you the contact information of our some other clients for you to check our credit. Besides, there is trade assurance from Alibaba, your order and money will be well guaranteed.

3.Can you give warranty of your products?

A: Yes, we extend a 100% satisfaction guarantee on all items. Please feel free to feedback immediately if you are not pleased with our quality or service.

4.Where are you? Can I visit you?

A: Sure,welcome to you visit our factory at any time.

5.How about the delivery time?

A: Within 15-35 days after we confirm you requirement.

6.what kind of payment does your company support?

A: T/T, 100% L/C at sight, Cash, Western Union are all accepted if you have other payment,please cont

Aluminum grade comparison

|

China |

Germany |

Europe |

International Standards |

USA |

Japan |

||

|

GB |

DIN |

EN |

ISO |

UNS |

JIS |

||

|

TU2 |

OF-Cu |

2.0040 |

Cu-OFE |

CW009A |

Cu-OF |

C10100 |

C1011 |

|

|

SE-Cu |

2.0070 |

Cu-HCP |

CW021A |

|

C10300 |

|

|

|

SE-Cu |

2.0070 |

Cu-PHC |

CW020A |

|

C10300 |

|

|

T2 |

E-Cu58 |

2.0065 |

Cu-ETP |

CW004A |

Cu-ETP |

C11000 |

C1100 |

|

TP2 |

SF-Cu |

2.0090 |

Cu-DHP |

CW024A |

Cu-DHP |

C12200 |

C1220 |

|

|

SF-Cu |

2.0090 |

Cu-DHP |

CW024A |

Cu-DHP |

C12200 |

C1220 |

|

|

SF-Cu |

2.0090 |

Cu-DHP |

CW024A |

Cu-DLP |

C12200 |

C1220 |

|

TPI |

SW-Cu |

2.0076 |

Cu-DLP |

CW023A |

Cu-DLP |

C12000 |

C1201 |

|

H96 |

CuZn5 |

2.0220 |

CuZn5 |

CE500L |

CuZn5 |

C21000 |

C2100 |

|

H90 |

CuZn10 |

2.0230 |

CuZn10 |

CW501L |

CuZn10 |

C22000 |

C2200 |

|

H85 |

CuZn15 |

2.0240 |

CuZn15 |

CW502L |

CuZn15 |

C23000 |

C2300 |

|

H80 |

CuZn20 |

2.0250 |

CuZn20 |

CW503L |

CuZn20 |

C24000 |

C2400 |

|

H70 |

CuZn30 |

2.0265 |

CuZn30 |

CW505L |

CuZn30 |

C26000 |

C2600 |

|

H68 |

CuZn33 |

2.0280 |

CuZn33 |

CW506L |

CuZn35 |

C26800 |

C2680 |

|

H65 |

CuZn36 |

2.0335 |

CuZn36 |

CW507L |

CuZn35 |

C27000 |

C2700 |

|

H63 |

CuZn37 |

2.0321 |

CuZn37 |

CW508L |

CuZn37 |

C27200 |

C2720 |

|

HPb63-3 |

CuZn36Pb1.5 |

2.0331 |

CuZn35Pb1 |

CW600N |

CuZn35Pb1 |

C34000 |

C3501 |

|

HPb63-3 |

CuZn36Pb1.5 |

2.0331 |

CuZn35Pb2 |

CW601N |

CuZn34Pb2 |

C34200 |

|

|

H62 |

CuZn40 |

2.0360 |

CuZn40 |

CW509N |

CuZn40 |

C28000 |

C3712 |

|

H60 |

CuZn38Pb1.5 |

2.0371 |

CuZn38Pb2 |

CW608N |

CuZn37Pb2 |

C35000 |

|

|

HPb63-3 |

CuZn36Pb3 |

2.0375 |

CuZn36Pb3 |

CW603N |

CuZn36Pb3 |

C36000 |

C3601 |

|

HPb59-1 |

CuZn39Pb2 |

2.0380 |

CuZn39Pb2 |

CW612N |

CuZn38Pb2 |

C37700 |

C3771 |

|

HPb58-2.5 |

CuZn39Pb3 |

2.0401 |

CuZn39Pb3 |

CW614N |

CuZn39Pb3 |

C38500 |

C3603 |

|

|

CuZn40Pb2 |

2.0402 |

CuZn40Pb2 |

CW617N |

CuZn40Pb2 |

C38000 |

C3771 |

|

|

CuZn28Sn1 |

2.0470 |

CuZn28SnlAs |

CW706R |

CuZn28Sn1 |

C68800 |

C4430 |

|

|

CuZn31Si1 |

2.0490 |

CuZn31Sil |

CW708R |

CuZn31Sil |

C44300 |

|

|

|

CuZn20Al2 |

2.0460 |

CuZn20Al2As |

CW702R |

CuZn20Al2 |

C68700 |

C6870 |

|

QSn4-0.3 |

CuSn4 |

2.1016 |

CuSn4 |

CW450K |

CuSn4 |

C51100 |

C5111 |

|

|

CuSn5 |

2.1018 |

CuSn5 |

CW451K |

CuSn5 |

C51000 |

C5102 |

|

QSn6.5-0.1 |

CuSn6 |

2.1020 |

CuSn6 |

CW452K |

CuSn6 |

C51900 |

C5191 |

|

QSn8-0.3 |

CuSn8 |

2.1030 |

CuSn8 |

CW453K |

CuSn8 |

C52100 |

C5210 |

|

BZn12-24 |

CuNi12Zn24 |

2.0730 |

CuNi12Zn24 |

CW403J |

CuNi12Zn24 |

C75700 |

|

|

BZn12-26 |

CuNi18Zn27 |

2.0742 |

CuNi18Zn27 |

CW410J |

CuNi18Zn27 |

C77000 |

C7701 |

|

BZn18-18 |

CuNi18Zn20 |

2.0740 |

CuNi18Zn20 |

CW409J |

CuNi18Zn20 |

C76400 |

C7521 |

|

|

CuNi10Fe1Mn |

2.0872 |

CuNi10Fe1Mn |

CW352H |

CuNi10Fe1Mn |

C70600 |

C7060 |

|

|

CuNi30MnlFe |

2.8820 |

CuNi30Mn1Fe |

CW354H |

CuNi30MnlFe |

C71500 |

C7150 |

Related Products

If you have any questions, we will sincerely answer for you!