Product Category

Galvanized Pipe Fittings

The water supply system generally adopts galvanized plastic-lined wire mouth elbow and clamp elbow, the fire protection system generally adopts galvanized wire mouth elbow and clamp elbow, and the electric system generally adopts the big moon elbow and the hydraulic device to make the elbow fittings.

Category:

Keywords:

Galvanized Pipe Fittings

Tel:

E-mail:

DETAILS

Chemical Composition

| Standard | Grade | C | Si | Mn | P | S | Ti |

| For cold forming Chinese standards | DX51D+Z | 0.12 | 0.50 | 0.60 | 0.100 | 0.045 | 0.30 |

| DX52D+Z | 0.12 | 0.50 | 0.60 | 0.100 | 0.045 | 0.30 | |

| DX53D+Z | 0.12 | 0.50 | 0.60 | 0.100 | 0.045 | 0.30 | |

| DX54D+Z | 0.12 | 0.50 | 0.60 | 0.100 | 0.045 | 0.30 | |

| DX56D+Z | 0.12 | 0.50 | 0.60 | 0.100 | 0.045 | 0.30 | |

| DX57D+Z | 0.12 | 0.50 | 0.60 | 0.100 | 0.045 | 0.30 | |

| For cold forming Japanese standards | SGCC | 0.15 | 0.50 | 0.80 | 0.050 | 0.030 | 0.025 |

| SGCD1SGCD2 | 0.120.10 | 0.500.50 | 0.600.45 | 0.0400.030 | 0.0300.030 | 0.0250.025 | |

| SGCD3 | 0.08 | 0.50 | 0.45 | 0.030 | 0.030 | 0.025 | |

| SGCD4 | 0.06 | 0.50 | 0.45 | 0.030 | 0.030 | 0.025 | |

| For structural Japanese standards | SGC340 | 0.25 | 0.50 | 1.70 | 0.200 | 0.035 | 0.025 |

| SGC400SGC440 | 0.250.25 | 0.500.50 | 1.702.00 | 0.2000.200 | 0.0350.035 | 0.1500.150 | |

| SGC490 | 0.30 | 0.50 | 2.00 | 0.200 | 0.035 | 0.025 | |

| SGC510 | 0.30 | 0.50 | 2.50 | 0.200 | 0.035 | 0.025 | |

| For structural AISI standards | S220GD+Z | 0.20 | 0.60 | 0.70 | 0.100 | 0.045 | 0.025 |

| S250GD+Z | 0.20 | 0.60 | 0.70 | 0.100 | 0.045 | 0.025 | |

| S280GD+Z | 0.20 | 0.60 | 0.70 | 0.100 | 0.045 | 0.025 | |

| S320GD+Z | 0.20 | 0.60 | 0.70 | 0.100 | 0.045 | 0.025 | |

| S350GD+Z | 0.20 | 0.60 | 0.70 | 0.100 | 0.045 | 0.150 | |

| S550GD+Z | 0.20 | 0.60 | 0.70 | 0.100 | 0.045 | 0.150 |

Mechanical Property

| Grade | Yield StrengthMPa≥ | Tensile StrengthMPa≥ | ElongationA%≥ |

| DX51D+Z/ZM/AZ/AM | 240-380 | 270-500 | 22 |

| DX52D+Z/ZM/AZ/AM | 140-300 | 270-420 | 26 |

| DX53D+Z/ZM/AZ/AM | 140-260 | 270-380 | 30 |

| DX54D+Z/ZM/AZ/AM | 120-220 | 260-350 | 36 |

| S220GD+Z/ZM/AM | 220 | 300 | 20 |

| S250GD+Z/ZM/AZ/AM | 250 | 330 | 19 |

| S280GD+Z/ZM/AM | 280 | 360 | 18 |

| S300GD+AZ/AM | 300 | 380 | 18 |

| S320GD+Z/ZM/AM | 320 | 390 | 17 |

| S350GD+Z/ZM/AZ/AM | 350 | 420 | 16 |

| S450GD+AZ/AM | 450 | 480 | 15 |

| S550GD+Z/ZM/AZ/AM | 550 | 550 | - |

Galvanized Surface Selection

| Zero Zinc Flower | Small Zinc Flower | Normal Zinc Flower | Big Zinc Flower |

|

|

|

|

| Usage Environment | Recommended zinc layer thickness |

| Indoor Use | Z10/Z12 (100g/㎡or 120g/㎡) |

| Suburbs | Z20and paint(200g/㎡) |

| Urban or industrial area | Z27(270g/㎡) /G90(US Standard) and painted |

| Coastal areas | Thicker than Z27 (270g/㎡) or G90 (US standard) and painted |

| Stamping or deep drawing applications | Thinner than Z27 (270g/㎡) or G90 (US standard) to avoid coating peeling after stamping |

| Surface Treatment Type | Code | Feature |

| Chromic acid treatment | C | Good corrosion resistance, suitable for exposure |

| Chromic acid treatment + oiling | S | Good corrosion resistance |

| Phosphoric acid treatment (including sealing treatment) | P | Has certain corrosion resistance and good paint performance |

| Phosphoric acid treatment (including sealing treatment) + oiling | Q | Has certain corrosion resistance, good paint performance, and prevents rust during transportation and storage |

| Phosphoric acid treatment (excluding sealing treatment) | T | Has certain corrosion resistance and good paint performance |

| Phosphoric acid treatment (excluding sealing treatment) + oiling | V | Has certain corrosion resistance, good paint performance, and prevents rust |

| Oiling | O | Prevent rust during transportation and storage |

| No treatment | M | Suitable for immediate painting |

Material comparison

| Chinese Standard | Japanese Standard | European Standard |

| DX51D+Z/DC51D+Z (CR) | SGCC | DX51D+Z |

| DX52D+Z/DC52D+Z | SGCD1 | DX52D+Z |

| DX53D+Z/DC53D+Z/DX54D+Z/DC54D+Z | SGCD2/SGCD3 | DX53D+Z/DX54D+Z |

| S220/250/280/320/350/550GD+Z | SGC340/400/440/490/570 | S220/250/280/320/350GD+Z |

| DX51D+Z/DD51D+Z (HR) | SGHC | DX51D+Z |

Product advantages

Business advantage

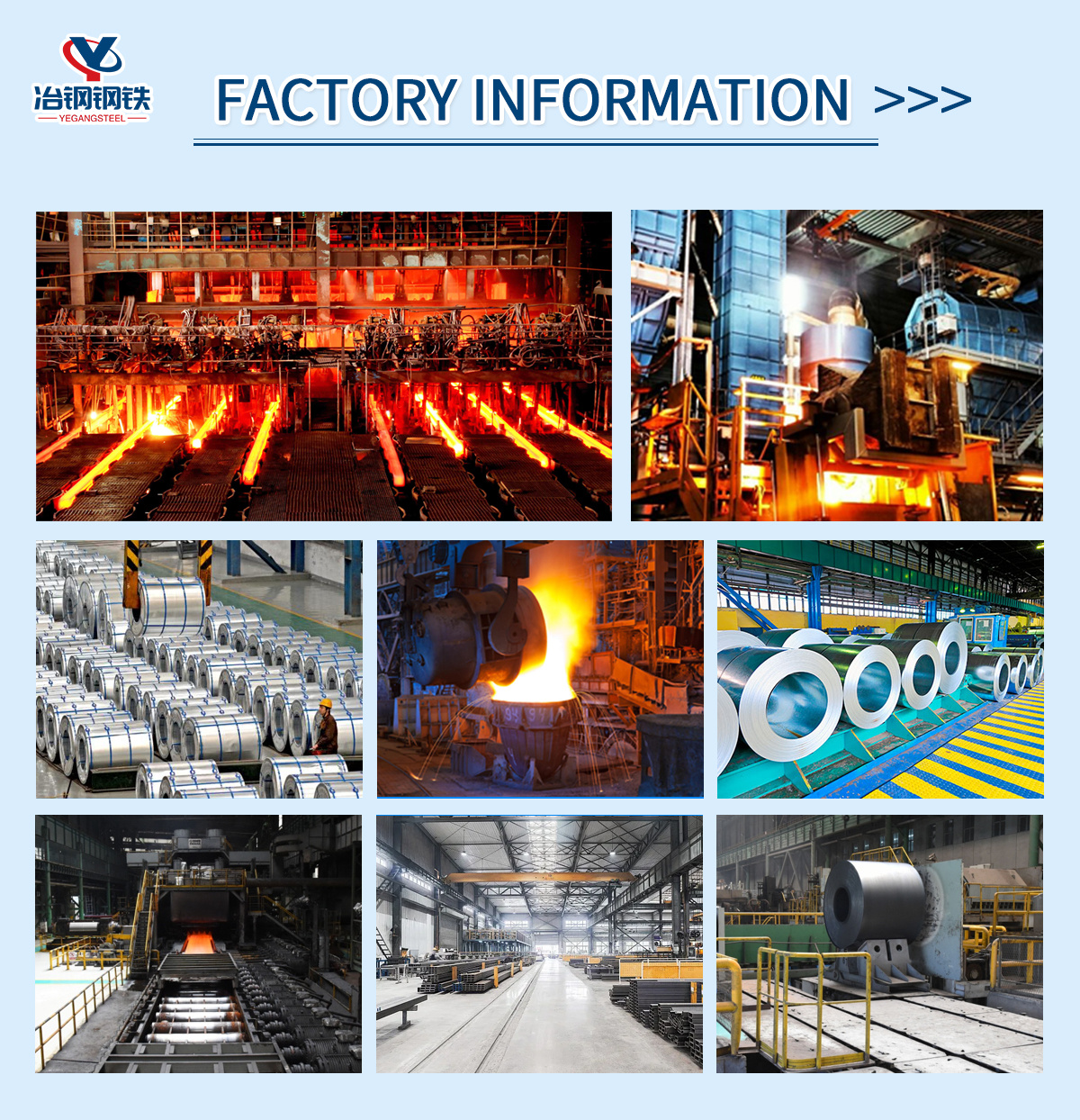

Factory information

Customer visits and certificates

Customer testimonials

Why Choose us:

1.Quality:

We are professional symbol ofChinese Metal industry; so all the supplied metal products from MAXIare quality researched & guaranteed well ones. Quality is our life. No quality, no biz.

2.Price:

Based on mature and rich acknowledge & experience forstainless steel and alloy steel, MAXIMETAL's supplied price could ensure customer has unique competitiveness in the market.As our aim is long-term biz instead of only profit by 1 or 2 order, we understand only customer win, we could win.

3.Delivery:

MAXIis one of TOP 10manufacturer of stainless steel and alloy products in China, Hold 10000tons raw materials in stock,has its own rolling factory,So enjoy high priority for delivery: Usually within 10-15from deposit date.

4.Payment:

MAXIsupply 30% TT IN ADVANCE + 70% TT WITHIN 7 DAYS OF BL DATE or IRR L/C AT SIGHT for customers. And with cooperation's growing & mature, better & better payment term will be issued, such as: L/C 30 DAYS, L/C 60 DAYS, L/C 360 DAYS, etc.

5.Service:

From MAXI, what customer could get is not only product, but also complete comprehensive marketting concept & service.

FAQ

1.What's your advantage?

A: Honest business with competitive price and professional service on export process.

2. How I believe you?

A : We consider honest as the life of our company, we can tell you the contact information of our some other clients for you to check our credit. Besides, there is trade assurance from Alibaba, your order and money will be well guaranteed.

3.Can you give warranty of your products?

A: Yes, we extend a 100% satisfaction guarantee on all items. Please feel free to feedback immediately if you are not pleased with our quality or service.

4.Where are you? Can I visit you?

A: Sure,welcome to you visit our factory at any time.

5.How about the delivery time?

A: Within 15-35 days after we confirm you requirement.

6.what kind of payment does your company support?

A: T/T, 100% L/C at sight, Cash, Western Union are all accepted if you have other payment,please cont

Galvanized material comparison table

| Chinese Standard | Japanese Standard | European Standard |

| DX51D+Z/DC51D+Z (CR) | SGCC | DX51D+Z |

| DX52D+Z/DC52D+Z | SGCD1 | DX52D+Z |

| DX53D+Z/DC53D+Z/DX54D+Z/DC54D+Z | SGCD2/SGCD3 | DX53D+Z/DX54D+Z |

| S220/250/280/320/350/550GD+Z | SGC340/400/440/490/570 | S220/250/280/320/350GD+Z |

| DX51D+Z/DD51D+Z (HR) | SGHC | DX51D+Z |

Related Products

If you have any questions, we will sincerely answer for you!